Proprietary Components

Patented parts remedy age old industry problems. Staples that affix the Tilt bar to the louver is been a shutters weak link. Our Louver Connector eliminates breaking or staple failure. Our part is designed link a ring-shank nail or barbed to create a mechanical contact with the louver and tilt bar. It is a part designed specifically for this tilting function. It is not a micro-penny part adapted to patch together an otherwise quality product.

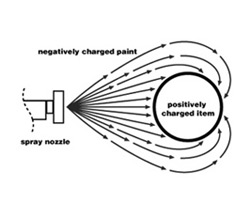

Embedded discrete all metal magnets ensure longevity and won't fail or break like exposed plastic "box' magnets (kitchen cabinet magnets). Not only is the discrete magnet unobtrusive as it is not visible from outside the home, it is a stronger component.

Rabbeted inner panel hinges wrap around or follow the rabbeted shape to ensure uniform clearance and unobtrusive visuals from outside your home.